ESL Labs offers advanced dynamic testing services for military, aerospace, transportation, and industrial applications.

Our laboratory is equipped to simulate a wide range of shock and vibration scenarios, from military-grade impact testing to commercial transport vibration conditions.

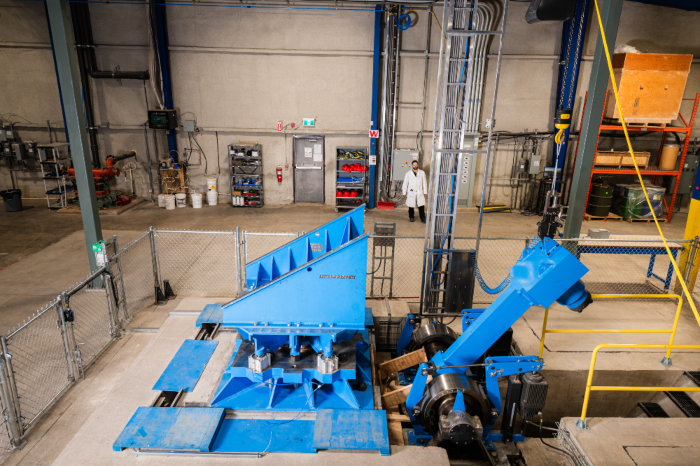

With the addition of our Medium Weight Shock Machine (MWSM) — one of only two in Canada — we now provide MIL-DTL-901E compliant testing for shipboard equipment and mission-critical systems.

Vibration Testing Capabilities

Our advanced vibration testing systems help evaluate product durability and operational integrity in harsh conditions. We simulate transportation, operational, and environmental vibration profiles for everything from trucking and freight logistics to military tracked vehicles, and air transport.

Electrodynamic Shaker

- Force: 12,000 lbf rms

- Modes: Sine, Random, Mixed-Mode Vibration & Shock

- Limits: Up to 100 g, 50.8 mm (2 in) displacement, 1778 mm/sec (70 in/sec)

Loose Cargo Vibration Testing

- Bed Size: 1.57 x 1.70 m (48 x 52 in)

- Max Payload: 568 kg (1250 lb)

- Motion: Circular synchronous and vertical linear motion

- Speed: 150–300 RPM

- Standards: ASTM D-999, ISTA, MIL-STD-810

Shock Testing Services

We simulate shock pulses and drops to test equipment resistance to sudden impact and mechanical stress.

Classic Shock Pulses

- Types: Half-sine, sawtooth, trapezoidal

- Duration: 0.5 to 30 msec

- Shock: Up to 70 g on shaker or 1000+ g on MRAD drop shock machine

- Shock Response Spectrum (SRS) Analysis: Evaluate system behavior under varying frequencies and magnitudes.

Drop Shock Testing

- Heights: Up to 11.8 m (30 ft)

- Simulates: Handling, transport, and operational drop scenarios

Navy High-Impact Shock Testing

(MIL-S-901 and MIL-DTL-901E)

We provide certified Navy shock testing services using both Lightweight and Medium Weight Shock Machines.

Lightweight Shock Machine (LWSM)

- Supports naval equipment up to 250 kg (550 lb) total.

- Complies with MIL-DTL-901E

Medium Weight Shock Machine (MWSM)

ESL Labs is proud to offer MIL-DTL-901E certified testing with our newly installed MWSM — a rare capability in North America. This capability supports defence contractors, marine system integrators, and government agencies in verifying equipment durability under naval combat conditions.

- Simulates high-energy underwater shock loads

- Designed to test mission-critical components for naval vessels

- Supports equipment up to 3300 kg (7400 lb) total

- Installed with 20–50 m³ of concrete foundation to handle extreme loads

- One of only 2 in Canada and 18 MWSMs in the world

Why Dynamic Testing Matters

• Identify weaknesses in design under vibration fatigue and shock loads

• Validate products for military, aerospace, and industrial compliance

• Prevent component failure due to wear, loosened fasteners, and connectivity issues

• Ensure product reliability in harsh environments

Dynamic Testing Facts

The goal of shock testing is to measure the device’s response time.

Vibrations have been known to cause excessive wear, loosen fasteners, loosen connections, damage components, and cause devices to malfunction.

Equipment designed for rugged or hostile environments needs to withstand a lot of vibration without breaking down or wearing out prematurely.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.