At ESL Labs, we provide advanced pressure testing services designed to simulate the most demanding real-world conditions.

From hydrostatic pressure testing at oceanic depths to explosive decompression testing simulating aircraft failures at high altitudes of 25,000 m (80,000 ft), our lab is equipped to ensure the safety, reliability, and performance of your components and systems.

Why Pressure Testing Matters

Pressure testing is a critical validation method used across industries such as aerospace, marine, military, and energy. It verifies:

- Leak tightness

- Mechanical strength

- Operational reliability under real-world stress

By simulating actual operating conditions, our pressure testing methods reduce failure risks in the field and ensure compliance with safety standards.

Internal Pressure Testing Services

We conduct hydrostatic and air pressure tests to verify the structural integrity and leak resistance of pressure vessels and other critical components.

Hydrostatic Testing: offers safer testing with minimal stored energy. Ideal for detecting leaks and ensuring long-term durability.

Air Pressure Testing: suitable for low-energy systems or where water ingress is not permissible.

External Pressure Testing Capabilities

Our external pressure chambers simulate extreme underwater environments and vacuum conditions:

Low Pressure Chamber

- Up to 8.8 MPa (1,200 psi)

- Chamber size: 2.5m long × 1m diameter

High Pressure Chamber

- Up to 100 MPa (15,000 psi)

- Chamber size: 1.2m long × 0.302m diameter

These capabilities support the qualification of subsea equipment, deep-sea sensors, and pressure housings.

Altitude Simulation and Decompression Testing

ESL Labs is equipped to test devices for high-altitude performance and emergency pressure scenarios.

Altitude Chamber

- Simulates up to 24,384 m (80,000 ft)

- Volume: 1 cubic meter

- Controlled temperature testing up to 18,288 m (60,000 ft)

Rapid Decompression

From 12,192 m (40,000 ft) to 3,048 m (10,000 ft) in seconds.

Explosive Decompression

From 12,192 m (40,000 ft) to 3,048 m (10,000 ft) in fractions of seconds.

These tests are essential for aerospace and avionics components, ensuring functionality in sudden cabin depressurization scenarios.

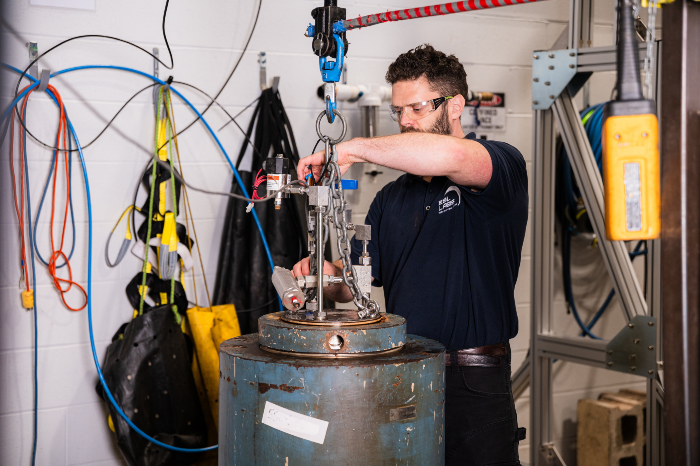

Our Pressure Testing Process

1. Preparation – Equipment is securely mounted and inspected.

2. Filling – The test chamber is filled with liquid (for hydrostatic) or air, often dyed for leak detection.

3. Pressurization – Pressure is gradually applied to the specified test level.

4. Monitoring – All readings are continuously logged, and results are reviewed against test criteria.

5. Documentation – A full report is issued, including data logs and compliance certifications.

Industries We Serve

Whether you're testing an underwater sensor, a pressure vessel, or aerospace avionics, ESL Labs provides the expertise and technology you need to certify performance and safety.

Pressure Testing Facts: What You Need to Know

Pressure testing is a critical step in verifying the structural integrity and performance of pressurized systems across industries such as aerospace, marine, manufacturing, and energy. It ensures three core outcomes: safety, reliability, and leak-tightness.

Why Pressure Testing Is Performed

Pressure testing helps identify potential weaknesses or defects in pressure vessels, pipes, valves, seals, or housings before they are deployed in the field. This process is especially important in safety-critical applications, where failure could lead to catastrophic results – including equipment damage, environmental harm, or injury.

How Pressure Testing Works

The process typically involves filling the system with a non-compressible liquid (usually water), which is sometimes dyed to aid in visual leak detection. Once the vessel is filled, it is gradually pressurized to a specific level that often exceeds its normal operating pressure. The system is then monitored for pressure drops, material deformation, or visible leaks.

In air pressure testing, compressed gas (usually air or nitrogen) is used instead of liquid. This method is used for low-pressure systems or where fluid introduction is undesirable, but it carries greater risk due to the higher stored energy.

Why Hydrostatic Testing Is Preferred

Hydrostatic testing is widely regarded as the safest and most effective pressure testing method. Because liquids are nearly incompressible, they store significantly less energy under pressure than gases. This means that if a rupture or failure occurs during the test, the risk of an explosive release is minimized.

Benefits of Hydrostatic Testing Include:

- Lower risk to personnel and equipment

- Clear, visual confirmation of leaks

- Ability to test at pressures well above operating conditions

- Reliable data for certification and compliance

Hydrostatic testing is frequently used for pipelines, tanks, castings, housings, and other components that must operate under pressure in harsh or variable environments.

At ESL Labs, our pressure testing procedures are designed not only to meet international standards but also to give clients peace of mind that their systems will perform as intended in extreme conditions. Whether you're working at ocean depths or high-altitude aerospace environments, our precision testing ensures your systems are up to the task.

Ready to Get Started?

For more information or to schedule a pressure test, contact us at info@esl-labs.com or call (902) 464-9220.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.