At ESL Labs, we deliver comprehensive EMI and EMC testing services to help manufacturers ensure their products meet international electromagnetic compatibility (EMC) and interference (EMI) standards. Our goal is to make compliance testing straightforward and reliable—so your innovations perform flawlessly in the real world.

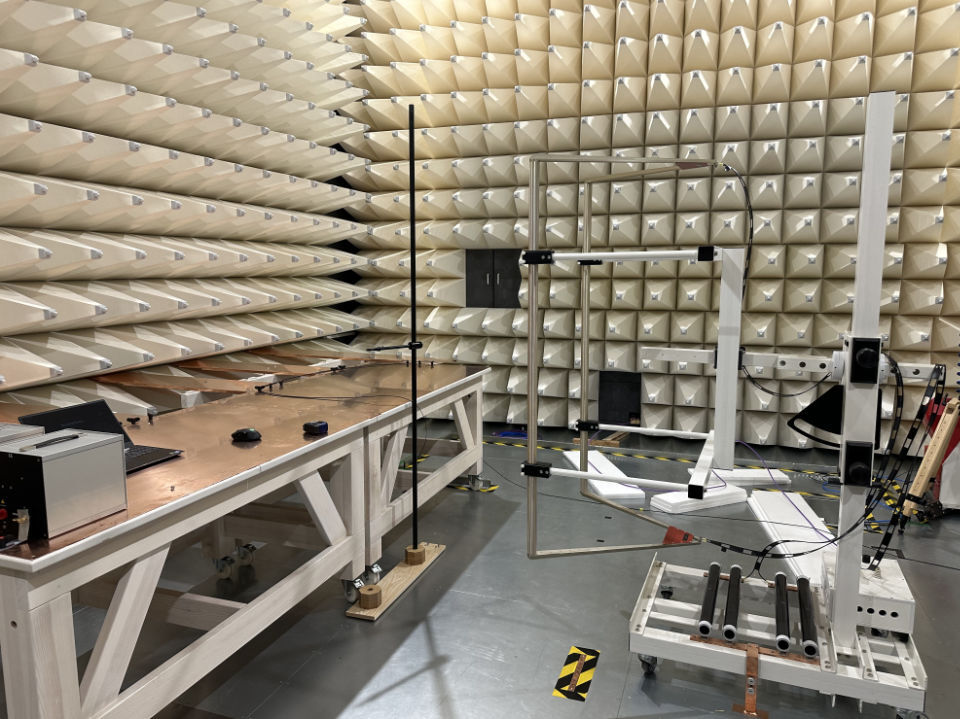

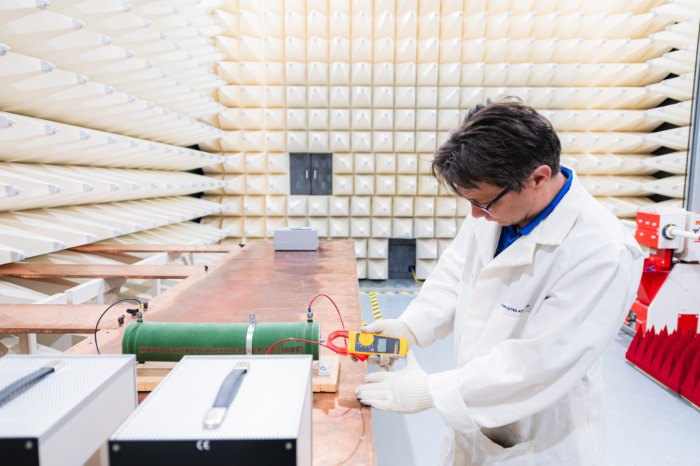

Our state-of-the-art facility features a Frankonia semi-anechoic EMI chamber, designed to facilitate comprehensive testing for conducted emissions, conducted susceptibility, radiated emissions, radiated susceptibility, and pre-compliance testing for various applications.

What Are EMI and EMC Testing — and Why They Matter

EMI (Electromagnetic Interference) testing identifies unwanted electromagnetic emissions from a device that may disrupt nearby electronics.

EMC (Electromagnetic Compatibility) testing ensures your equipment can operate properly in the presence of such emissions. In short, EMI and EMC testing confirm your product won’t cause or suffer from interference in its environment – critical for certification, safety, and performance.

New ESL Labs Facility with EMI Chamber

With almost 40,000 sq. ft. of space, the new testing facility for ESL Labs provides room to accommodate this state-of-the-art EMI and EMC testing capability.

The EMI semi-anechoic chamber is 9.68 m (L) x 6.53 m (W) x 6.00 m (H) with a 2m diameter turntable and 2000 kg capacity. This advanced Frankonia EMI chamber means ESL Labs can perform MIL-STD-461G testing on a variety of product sizes. The EMI chamber is comprised of anechoic cones and ferrite tiles to absorb electromagnetic radiation and to prevent any reflections from the walls, ceiling, or floor, creating a perfectly isolated testing environment.

The large size of the ESL chamber allows for tremendous flexibility when making decisions on what kind of test instrumentation can be used. Common testing instrumentation includes EMI receivers, signal generators, high-power RF amplifier racks, low frequency test sets, and high bandwidth digital oscilloscopes.

Our EMI and EMC Testing Capabilities

Our EMI and EMC testing services provide critical benchmarks for industries that require compliance with strict electromagnetic compatibility standards. ESL Labs serves customers across a range of sectors, including aerospace, defense, and commercial applications. Our EMI chamber testing capabilities cover:

- MIL-STD-461D/462D test methods

- DC magnetic field susceptibility

- Power quality test methods

- Commercial Radiated and Conducted Immunity

- RTCA/DO-160G EMI test methods

- Commercial RF transmitter/receiver (radio) test methods

- ESD (electrostatic discharge) testing

The Frankonia EMI chamber supports testing to MIL-STD-461G for a variety of applications, including surface ships, submarines, army aircraft, navy aircraft, space systems, and ground forces. At ESL Labs, we also provide testing for commercial applications, including radiated emissions, conducted emissions, and RTCA/DO-160G compliance.

EMI / EMC Testing Team

ESL Labs is proud to be able to provide a wide range of EMI / EMC engineering services, including:

- EMC Design (System, equipment, printed circuit board, power, cables)

- EMI Troubleshooting and Mitigation

- System-Level Electromagnetic Environmental Effects (E3)

- Electromagnetic Radiation Hazards (RADHAZ aka RF Safety)

- Indirect Lightning / High Intensity Radiated Fields (HIRF) Airworthiness

- Regulatory Compliance

- Emissions Security (EMSEC) (aka TEMPEST)

MIL-STD-461G Testing Areas

Our EMI chamber is fully equipped to perform a variety of tests in line with MIL-STD-461G, including:

- Conducted Emissions

- Conducted Susceptibility

- Radiated Emissions

- Radiated Susceptibility

- Electrical Bonding

RTCA/DO-160G

- Section 21 - Emission of Radio Frequency Energy

- Section 22 - Radio Frequency Susceptibility (Radiated and Conducted)

- Section 25 - Electrostatic Discharge

- Section 18 - Audio Frequency Conducted Susceptibility - Power Inputs

Commercial Radiated and Conducted Emissions

Our EMI chamber is used for testing in various EMI and EMC standards, including:

- ICES-003, Radiated and Conducted Emissions - Information Technology Equipment (ITE)

- ICES-001, Radiated and Conducted Emissions - Industrial, Scientific, and Medical (ISM)

- FCC Part 15B, Radiated and Conducted Emissions

- EN 55011/CISPR 11, Radiated and Conducted Emissions - ISM Equipment

- EN 55032/CISPR 32, Radiated and Conducted Emissions - Multimedia Equipment

Why Choose ESL Labs for EMI and EMC Testing?

State-of-the-Art Facility

Our new testing facility houses the Frankonia EMI semi-anechoic chamber, offering unmatched capabilities for EMI/EMC testing and compliance verification.

Comprehensive EMI/EMC Testing

From radiated emissions to conducted immunity, our testing services cover all aspects of electromagnetic compatibility.

Industry Expertise

With experience across aerospace, defence, and commercial sectors, ESL Labs is a trusted provider of EMI and EMC testing solutions for complex applications.

Contact ESL Labs for EMI and EMC Testing Solutions

If you require EMI/EMC testing for your products, ESL Labs is here to provide expert services that meet industry standards and ensure compliance. Contact us today to learn more about our EMI testing capabilities and how we can help your products achieve electromagnetic compatibility.

Frequently Asked Questions About EMI and EMC Testing

EMI (Electromagnetic Interference) and EMC (Electromagnetic Compatibility) testing evaluate how electronic devices emit and respond to electromagnetic energy. These tests ensure your equipment operates safely without interfering with other devices or being affected by external interference.

The difference lies in the focus of each test:

- EMI testing measures how much electromagnetic noise your product emits.

- EMC testing ensures your product can function properly even when exposed to electromagnetic noise from its environment.

Both are essential for ensuring compliance, reliability, and product safety.

Compliance testing is required by regulatory agencies and industry standards to ensure products don’t cause interference or fail due to electromagnetic exposure. Meeting EMI and EMC testing standards prevents costly recalls, protects users, and ensures your product can be legally sold in domestic and international markets.

EMI and EMC compliance testing is crucial for aerospace, defence, automotive, telecommunications, marine, and medical industries – any field where electronic equipment must operate reliably in high-interference environments.

ESL Labs performs testing according to major global and military standards, including:

- MIL-STD-461G / 462D

- RTCA/DO-160G

- FCC Part 15B

- ICES-001, ICES-003

- EN 55011, EN 55032 (CISPR 11/32)

Our engineers help identify the correct standard for your product’s intended use and certification region.

Yes. We provide pre-compliance EMI and EMC testing services to identify potential design issues early, saving you time and cost during final certification. This approach helps refine product design before submitting to full regulatory testing.

Testing timelines depend on the complexity of your product and the required standards. A typical pre-compliance test can take a few days, while full compliance certification may take one to two weeks or beyond. ESL Labs provides a detailed testing schedule as part of each project plan.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.

Ready to test your limits? Email us, give us a call at 902-464-9220, or visit us.